生物•医药

我 们 的 优 势 Advantage of corporation

汇通源成立于2006年,历经十年,我们一路向着专业,创新,研发奋力前行, 积累了丰富的医药行业工程实践经验,锻造出专业的技术团队。严格遵循中,美,欧《药品质量管理规范》,并落实在设计、制造、工程安装实施、验证、运行过程中。结合经验自主研发专业水处理技术,并引进吸取国际先进技术,一直致力于医药行业水处理解决方案,为众多国内外生物医药企业提供服务,支持系统的GMP,USP,EP认证,并获得了ISO9001与欧盟CE认证。我们期待你的选择,携手前行。

Huitongyuan was established in 2006, after ten years, us toward the professional, innovation, research and development of struggling forward, has accumulated a wealth of pharmaceutical industry engineering practice experience, forging a professional technical team. Strictly abide by, the United States, Europe "drug quality management norms", and implement in the design, manufacturing, engineering, installation, implementation, verification, operation process. Combined with experience independent research and development of professional water treatment technology, and the introduction of absorbing international advanced technology, has been working in the pharmaceutical industry water treatment solutions, to provide services for numerous domestic and foreign pharmaceutical enterprises, support system of GMP, USP, EP certification, and access to the ISO9001 and CE certification. We look forward to your choice, go hand in hand.

技 术 特 点 Technical characteristics

纯化水系统

我们对纯化水系统的设计以模块化概念设计为理念,使纯化水系统具有独立化,模块化,操作简易化特点,保证了设备运行的连续性,稳定性,可靠性,并根据客户水质报告和URs,作出两种以上的设计方案供客户选择。包括预处理配置,脱盐系统组合,分配系统选择,消毒方式等等,同时我们还为客户提供一套完整的验证系统包括前期设计确认,厂内的FAT测试,后期安装确认,运行确认和性能确认,以及完善售后处理。

purified water system

We of purified water system design module of conceptual design for the concept of the purified water system with independent, modular operation simple characteristics, to ensure the continuity of the equipment operation, stability, reliability, and according to customer quality report and saurs, make more than two kinds of design scheme for customers to choose. Including configuration pretreatment, desalination system, distribution system, disinfection and so on. At the same time, we also for customers to provide a complete set of verification system including pre design confirmation, plant fat test, post installation qualification, operational qualification and performance qualification and perfect after-sale.

多效蒸馏水机

蒸馏是通过气液相变法和分离法来对原料水进行化学和微生物纯化的工艺过程。在这个工艺当中被蒸发了,产生的蒸汽从水中脱离出来,而流到后面去的未蒸发的水溶解了固体,不挥发物质和高分子杂质。在蒸馏过程当中,低分子杂质,可能被夹带在被水蒸发后的蒸汽以水雾或水滴的形式被携带,所以需要通过一个分离装置来去除来去除细小水雾和夹带杂质,这其中包括内毒素。纯化了的蒸汽冷凝后成为注射用水,通过蒸馏方法至少能减少99.99%内含毒素量。

Multi effect distilled water machine

Distillation is by gas-liquid phase separation method and process for purification of chemical and microbiological of raw water In this process was evaporated, the steam generated from the water out of the flow into the back of the evaporated water to dissolve the solid, non volatile substances and polymer impurities. In the distillation process, the low molecular impurities may be entrained in after evaporation of water vapor in form of mist or droplets is carried, so it is necessary to through a separation unit to remove the to and fro in addition to fine water mist and entrained impurities, which consist of endotoxin. Purified steam is condensed into water for injection, and can be reduced by at least 99.99% of the content of the toxin by the distillation method.

纯蒸汽发生器

纯蒸汽发生器通常是以纯化水为原料水,通过纯蒸汽发生器或多效蒸馏水机的第一效蒸发器所制备蒸汽,纯蒸汽冷凝时要满足注射用水的要求,去离子水和纯化水都可作为纯蒸汽发生器的原料水,经蒸发。分离(去除微粒及细菌内毒素等污染物)后,在一定压力下输送到使用点。

Pure steam generator

Pure steam generator is usually with purified water as raw water, the pure steam generator or multi effect distilled water machine the first effect evaporator prepared by steam and condensation of the pure steam, to meet the requirements of the injection water, deionized water and purified water can be as pure steam generator feed water by evaporation. Separation (removal of particles and bacterial endotoxin, etc.), after a certain pressure to the use of. Perfect after sales processing.

我们的服务 Our service

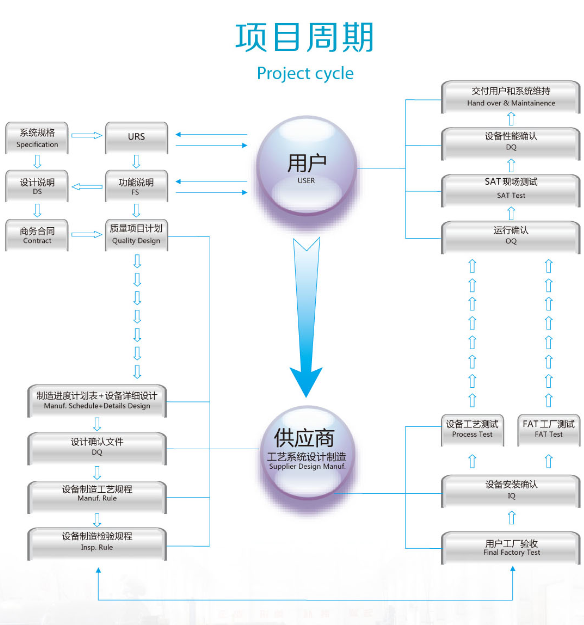

项 目 周 期 project cycle

硬 件 设 备 保 障 Hardware devices

精细管理

每一个微小的细节都值得我们密切关注,每一个细小行动都举足轻重.

Fine Management

Every minute detail deserves our close attention, and every little action is important.

精益生产

汇通源精益生产管理体系由成本定额控制体系,作业工时定额,工艺菜单体系,7S现场作业管理体系组成,以质量求生存,以管理求效益。

Lean production

Huitongyuan lean production management system by the cost quota control system, operation time quota, craft menu system, 7S on-site operations management system, to the quality of survival, to management for efficiency.

质 量 保 障 Quality assurance

为每一件产品提供高效可信赖的检测与质量控制

To provide efficient and reliable testing and quality control for each product

确保每道工序均满足用户的要求

Ensure that each process meets the user's requirements.

为使客户满意,我们倾尽全力

In order to satisfy the customer, we are doing our best.