Solution

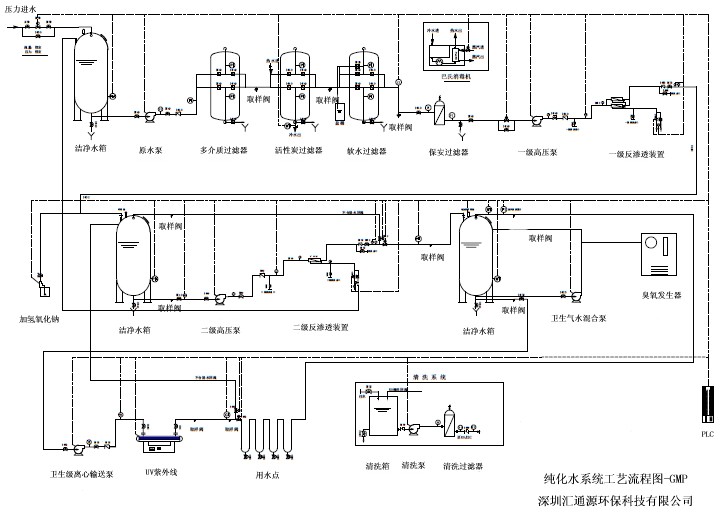

Solution of purified water system for oral and health care products

Time:2017-04-16 10:23:40

(1)In depth understanding of customer needs and product categories, give the most suitable equipment configuration, reference pharmaceutical GMP requirements。

(2)Purified water system without vulnerable parts, without a large number of maintenance, long-term stable and effective operation。

(3)Pre process protection system, the protection of high pressure pump and RO film is not damaged by particles or other hard objects; at the same time low voltage switch to protect the high-pressure pump, the pressure is not too low and damaged. If the water supply is interrupted or under pressure, the system will automatically shut down。

(4) advanced membrane protection system, when the device is turned on, the device automatically send rinse the membrane physical action, with high water pressure generated by the high-pressure pump to clean the membrane surface pollutants and reduce the pollution rate, prolong the service life of the membrane。

(5)Polyamide composite (TFC) membrane desalination rate is high, to ensure the efficiency of the operation of the system。

(6)Each of the product water and concentrated water is provided with a flow meter to monitor and regulate the running water and water use efficiency。

(7)Continuous on-line monitoring of water quality of raw water, RO water production and water production conductivity meter. The water inlet and drainage pressure gauge, continuous monitoring of RO membrane pressure, suggesting that the washing time and the design of membrane chemical cleaning device.

(8)The whole system PLC, touch screen control, and with sound and light alarm system。

(9)Quartz sand, activated carbon, one or two reverse osmosis, the use of more than 80 degrees Celsius hot water for regular disinfection。

(10)The first stage reverse osmosis RO membrane was cleaned and sterilized by chemical reagent.。

(11)The whole set of equipment using PLC, touch screen full automatic intelligent control, water quality throughout the online monitoring, equipment running without manual monitoring. Equipment operating and design based on simple and easy to control principles, only in the operation of the cabinet panel operation, the operator can be safe, easy and simple operation。

On line control;。

Temperature online - temperature sensor (alarm, signal output)。

Pressure on line - clean diaphragm pressure gauge。

Conductivity Online - clean conductivity meter (alarm, signal output)。

PH online ---- clean PH online detector (alarm, signal output)。

Flow on line --- clean flow sensor (alarm, signal output)。

Risk Management:

Quartz sand, activated carbon - regular sterilization (record, verification)。

Reverse osmosis: regular cleaning, regular Pap test (record, verification)。

Two stage reverse osmosis - regular cleaning, regular sterilization (record, verification)。

Two reverse osmosis water production --- online water quality testing (conductivity, PH), critical alarm, non-compliance alarm (line switch, not up to the water back to the original water tank)

Tank - regular pasteurization (record and verification)

Transport unit - the health class booster pump, substandard water (electrical conductivity, PH) critical alarm, non-compliance alarm (line switch, not up to the water back to the original water tank)

Backwater part -- double tubesheet heat exchanger regular Pap sterilization (record and verification), flow rate and temperature online detection, conductivity, pH is not up to the standard alarm (pipeline switch, substandard water back to the original water tank)

Reference flow